How Real-Time Data is Powering Industrial IoT

In the not-so-distant past, industrial automation meant reactive systems — machines that operated by pre-written rules and responded only when something went wrong. But today, with the rise of edge computing, factories, logistics centers, and production lines are gaining the ability to think and act in real time. This shift, powered by AI models running directly at the edge of the network, is transforming how industries operate.

Edge-driven automation allows companies to move decision-making closer to the data source — whether it’s a conveyor belt sensor, a robotic welding arm, or a vibration meter on a pump. With the help of solutions from companies like 0xMetaLabs, manufacturers and logistics operators are now able to predict failures before they happen, inspect products while they move down the line, and optimize energy use from minute to minute.

This isn’t just about faster processing — it’s about redefining how industrial systems make decisions.

The Rise of Edge Intelligence in Industrial Systems

For decades, industrial data was collected and transmitted to centralized servers for processing, often in the cloud. While this model works well for reporting, it introduces serious latency issues for real-time actions. Waiting even a few seconds to detect a machine fault or confirm a quality anomaly can result in defective products, system failures, or even safety hazards.

Edge computing changes this equation.

Edge devices are now capable of running complex machine learning models locally. This means they don’t need to ask a distant server what to do — they can analyze incoming sensor data and decide on the spot. These decisions range from subtle (slowing a motor based on temperature patterns) to critical (shutting down a conveyor belt after detecting a safety risk).

This immediacy has enormous implications for industries where speed, uptime, and reliability are non-negotiable.

Why Real-Time Decision-Making Is a Game-Changer

The value of edge-driven automation lies in its ability to support intelligent, autonomous systems that reduce human intervention, streamline operations, and cut costs.

- Latency Reduction: In automated factories or high-speed logistics environments, milliseconds matter. Edge processing ensures that decisions, like stopping a robotic arm or flagging a misaligned package, are executed without delay.

- Operational Resilience: Remote or rugged environments often experience connectivity issues. Unlike cloud-based systems, edge devices can continue to function independently, even if the network goes down.

- Cost and Bandwidth Savings: Streaming high-volume sensor data to the cloud for processing is expensive and inefficient. Edge computing reduces the burden by filtering and processing data locally, sending only actionable insights upstream.

- Security and Privacy: Edge systems can also help organizations meet data protection regulations by keeping sensitive information on-premises. This is especially important in industries like pharmaceuticals or energy, where compliance and IP protection are critical.

Real-World Applications of Edge AI in Industry

The theory behind edge automation is powerful, but its impact is most compelling in the field.

1. Predictive Maintenance

Industrial assets like pumps, turbines, and motors often fail not suddenly, but gradually, through small shifts in vibration, temperature, or sound. Edge AI systems trained on normal behaviour can recognise the early signs of trouble. They can forecast when a component is likely to fail, and automatically trigger maintenance schedules or parts orders before the problem escalates.

At scale, this prevents unplanned downtime, which costs industries more than $1.4 trillion globally every year.

Systems built by providers like 0xMetaLabs combine time-series analysis with sensor fusion to deliver extremely accurate diagnostics. These edge systems often run on microcontrollers or compact GPUs and can be deployed on existing machinery without overhauling legacy infrastructure.

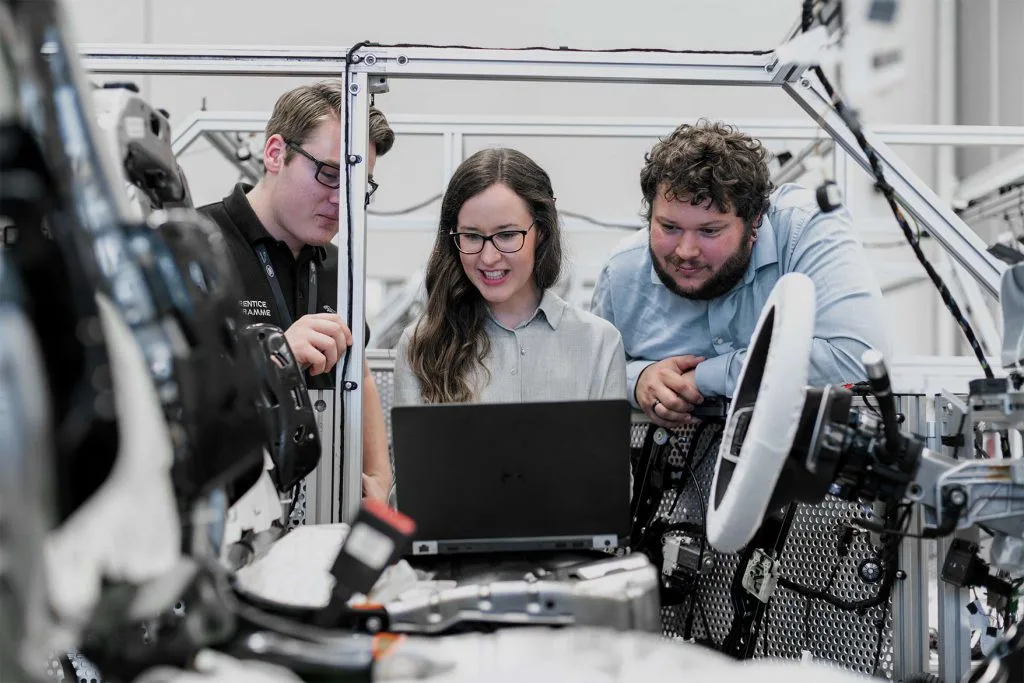

2. Quality Control and Defect Detection

In a traditional setup, quality checks often happen after production is complete. By then, a whole batch could be compromised. Edge AI changes this by enabling real-time inspection — analyzing images, weights, dimensions, or even surface patterns while items are still on the line.

Computer vision models deployed at the edge can flag imperfections, segregate defective units, or fine-tune machinery on the fly. In sectors like food packaging, automotive assembly, and electronics, this means fewer recalls, reduced waste, and better customer satisfaction.

One notable example involves the use of AI-enabled cameras in steel mills, where worker safety and product uniformity depend on millisecond-level analysis. Edge systems ensure that humans aren’t put at risk and that flawed products don’t leave the floor.

3. Smart Process Optimization

Edge systems also help factories optimize energy use, material flow, and equipment calibration. Because they operate continuously and adjust dynamically, they reduce waste and improve consistency.

For example, in chemical manufacturing, slight variations in pressure or composition can have a huge impact on product quality. Edge AI can detect these subtle shifts and adjust input parameters automatically, reducing human error and improving output efficiency.

0xMetaLabs: Architecting Intelligence at the Edge

0xMetaLabs is one of the few companies building edge systems with a truly holistic design philosophy. Instead of focusing just on device performance or cloud integration, they approach edge deployment as an ecosystem.

- Their systems begin with ruggedized edge gateways that support real-time data collection from vibration sensors, thermocouples, optical devices, and more.

- They use modular AI frameworks optimized for edge inference, designed to run on low-power boards like NVIDIA Jetson, ESP32, or ARM Cortex processors.

- These devices run pre-trained models customised for each industry for classification, prediction, and anomaly detection.

- Continuous over-the-air updates ensure that models improve over time, based on site-specific learning.

Perhaps most important: their systems are designed to integrate with existing industrial infrastructure. Whether a factory uses legacy PLCs or newer SCADA environments, 0xMetaLabs bridges the gap with adapters and APIs, ensuring rapid deployment without ripping and replacing.

Overcoming the Challenges of Edge Deployment

While the benefits of edge-driven automation are clear, the road to implementation isn’t without obstacles.

- Skill Shortages: Edge systems require expertise in embedded AI, networking, and real-time system design. Upskilling teams or working with experienced partners is essential.

- Security: The more devices you place at the edge, the more endpoints need to be protected. From encrypted firmware to intrusion detection, security must be designed from the ground up.

- Interoperability: Many factories still operate with siloed, proprietary systems. Edge platforms need to connect across varied protocols — Modbus, OPC-UA, CANbus — to extract and act on data consistently.

- Scalability: While it’s easy to pilot edge AI in one location, scaling it to dozens of plants or distribution centers requires careful architecture planning, device management, and orchestration.

0xMetaLabs addresses these issues by offering a centralized platform for monitoring all deployed edge systems, combining live dashboards, health monitoring, and model version control in one place.

What the Future Looks Like

The next generation of edge-driven automation will be autonomous, collaborative, and adaptive.

- Federated Learning will allow edge devices to train together without sharing sensitive data, making AI models stronger and more private.

- Self-Healing Systems will not only detect anomalies but also take corrective action — rerouting operations or replacing failed components without human involvement.

- Edge-to-Cloud Feedback Loops will synchronize local decisions with global optimization models, allowing businesses to coordinate fleets of factories or distribution centers from a single control plane.

- AI-Enhanced Digital Twins will combine simulation with real-time edge data to model entire facilities, allowing engineers to test changes before applying them in the real world.

Conclusion

Edge-driven automation is more than a technological upgrade — it’s a new way of thinking about industrial systems. By moving intelligence to where data is generated, businesses gain speed, efficiency, and control.

For manufacturers and logistics companies under pressure to be faster, cleaner, and smarter, this isn’t optional — it’s essential. And for those looking to future-proof their operations, partners like 0xMetaLabs are helping bring that edge-powered future within reach.

The smart factory of tomorrow isn’t in the cloud. It’s at the edge — and it’s already online.

You May Also Like

How Hyperautomation is reshaping Business Operations

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo con

How Companies finally admitted they’re not Smarter than 3.8 Billion years of Evolution

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo con

Why Businesses Need Infrastructure Resilience Strategies

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo con